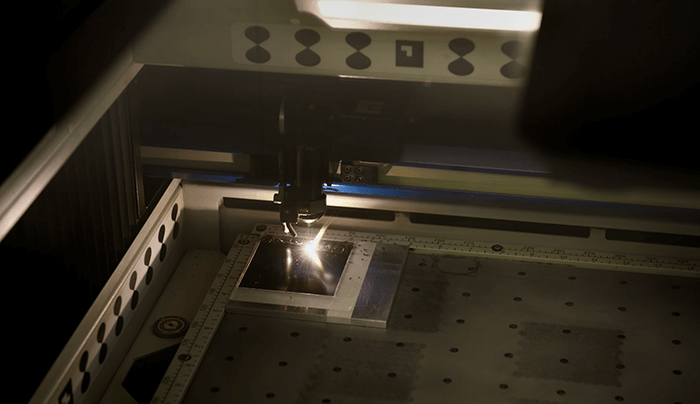

Laser Cutting

CO2 Laser Cutting

Key benefits of CO2 laser systems include:

- Minimal material waste

- Reduced need for post-processing

- High repeatability

- Ability to handle complex geometries with ease

- Integrated Vacuum Table – holds down thin material for precise cutting

- Cutting can be executed in patterns as drawn on a control screen

CO2 laser cutting is well suited for small runs, as a cost-effective alternative to steel rule dies. CO2 laser cutting can be used in etching and cutting applications involving a wide range of materials, including plastics other than vinyl, as well as wood, adhesives, solid service, and more. It is suitable for the etching of glass, but not specified for metal.

Laminating Laser Cut Materials

Laminating is the process of applying an additional layer to materials before or after the die-cutting process. Typically, Thrust Industries uses the laminating process to apply an adhesive to a substrate material, such as plastic film, rubber, or foam before laser cutting the component from that material. An adhesive, PSA or tape, can be added to one side or both sides of a material, with secondary liners where needed.

Our laminated materials are often used in industries like packaging, electronics, automotive, and signage, where precision, durability, and aesthetic appeal are important. The combination of laminating and die-cutting allows for the creation of high-quality, customized components that look great, meet industry standards, and perform reliably in any environment.

Laser Cutting Prototypes

Have a need for samples, prototypes, or engraving? You can count on Thrust Industries to deliver a quality product for you or your customer. Simply send us a computer-based program such as DXF, CAD, or Corel Draw and we will convert it into a product.

Our competitive converting prices help you keep costs down, and our wide stock of available material and access to the major distribution channels also translate to your advantage. Our laser cutting capabilities are highly beneficial when die cutting may not meet your needs.

Preco Jumbo Roll Laser Processing Machine

The Preco features a control system that operates in a user-friendly Windows® environment that allows both cross-web and simple shape processing. Changeovers are simple and do not require the need for costly tooling. Designed to handle large rolls of material, it offers significant benefits for high-volume, industrial-scale applications which result in enhanced efficiency and cost savings for our customers.

This large, turnkey system will be ideal for any of your high production requirements.

- Loose Discs

- Tabbed Discs

- Hook & Loop

- Stick-On Discs

- Disc Rolls

- Paper

- Cloth

- Hook & Loop

- Polymer

- Fiber

- Adhesives

- Laser Cutting

- Laser Kiss-Cutting

- Laser Slitting

- Laser Marking/Etching

- Laser Perforating

Epilog Laser Machines

For many years, we have done most of our laser cutting with two Epilog laser cutting machines. These reliable systems have served our customers well, alongside some of the more advanced systems we offer.

These tried and true machines offer many benefits for less complex projects, including versatility, speed, efficiency, and minimal waste.

Frequently Asked Questions About Laser Cutting

Thrust Industries can laser cut a variety of materials including paper, fabrics, thin plastics, wood, adhesives, and solid surfaces. However, we do not cut vinyl or metals.

CO2 laser cutting offers high precision and does not require physical contact with the material, making it ideal for intricate designs and small production runs. It also eliminates the need for expensive tooling. Plus, it’s cost-effective.

You’re in luck! Our Preco Jumbo Roll Laser Processing Machine is designed for high production requirements with capabilities for roll-to-roll part processing and easy changeovers.

Absolutely. Thrust Industries can produce high-quality prototypes and samples. Customers can provide designs in formats such as DXF, CAD, or Corel Draw.

Customers can send digital files in formats like DXF, CAD, or Corel Draw, which Thrust Industries will convert into a laser-cut product. They offer competitive pricing and have a stock of various materials.

While specific thickness limitations are not detailed, CO2 laser cutting is generally suitable for thin materials. For thicker materials, consultation with Thrust Industries is recommended.

Thrust Industries uses advanced laser cutting machines and integrated vacuum tables to hold materials in place, ensuring consistent and precise cuts. They also perform quality checks throughout the process.

Yes, Thrust Industries offers both laser cutting and etching services, suitable for various materials and applications.